Polymaker produces high-quality 3D printing materials with a comprehensive range of properties and functions, ranging from high engineering strength to unique aesthetic solutions.

Our Top Selling Filaments

Colours :

Regular Range

*pre-order (moq 5 unit, lead time 8 weeks)

Black

White

Blue

Yellow

Grey

Teal

Natural

Red

Green

Purple

(pre-order)

Orange

(pre-order)

.png)

Translucent Orange

(pre-order)

Net Weight

1 kg / 3 kg

Diameter Size

1.75 mm / 2.85 mm

Printing Settings

-

Printing temp: 190˚C - 230˚C

-

Printing speed: 40-60mm/s

-

Bed temp: 25˚C - 60˚C

-

Chamber temp: N/A

-

Annealing: N/A

-

Fan: On

-

Drying Settings: 55˚C for 6h

(Only if the material has absorbed moisture)

Application

PolyLite™ PLA is a reliable 3D printing material with a wide variety of colors.

It features strength and rigidity, this combination provides ease of printing with good mechanical properties which makes it a good candidate for product design, home gadgets, toys, trinkets, props, cosplay or prototyping.

PolyLite™ PLA has the widest range of special effect filaments with silk, dual silk, glow in the dark, galaxy, starlight, temperature color change and UV color change, all offering a different surface effect.

Key Features

Heat resistant

Impact

resistant

Machinable

Colours

*pre-order (moq 5 unit, lead time 8 weeks)

Black

White

Clear

Blue

Grey

Green

Red

Yellow

Orange

(pre-order)

Purple

(pre-order)

Polymaker Teal

(pre-order)

Net Weight

1 kg

Diameter Size

1.75 mm / 2.85 mm

Printing Settings

-

Printing temp: 220-250°C

-

Printing speed: 30-50mm/s

-

Bed temp: 70-80°C

-

Chamber temp: N/A

-

Fan: On

-

Dry settings: 70°C for 8h

-

Annealing: N/A

Application

PolyLite™ PETG is just as easy to print as PolyLite™ PLA while offering an additional 20˚C heat resistance and more durability.

This lends PolyLite™ PETG to more functional applications where PLA would lack the durability or heat resistance such as lighting fixtures, vibrational parts or more functional product design prototypes.

Key Features

Excellent all-rounder

Good layer adhesion

Good light diffusion

Colours :

*pre-order (moq 5 unit, lead time 8 weeks)

Black

.png)

Orange

(pre-order)

White

Blue

.png)

Red

.png)

Army Green

(pre-order)

.png)

Polymaker Teal

(pre-order)

.png)

Grey

(pre-order)

.png)

Natural

(pre-order)

Net Weight :

1 kg / 3 kg

Diameter Size :

1.75 mm / 2.85 mm

Printing Settings :

-

Printing temp: 240-260°C

-

Printing speed: 30-50mm/s

-

Bed temp: 75-95°C

-

Chamber temp: N/A

-

Fan: Off

-

Dry settings: 80°C for 8h

-

Annealing: N/A

Application :

PolyLite™ ASA has the same mechanical and thermal properties as PolyLite™ ABS with the ability to resist sunlight (UV) and weather in general.

Its good weather resistance makes it ideal for outdoor applications such as garden tools, outdoor decoration, parts that are in direct sunlight or exposed to the elements.

Key Features :

UV resistant

Water resistant

Good thermal and mechanical properties

Colours

*pre-order (moq 3 unit, lead time 6 weeks)

Black

White

Grey

(pre-order)

Polymaker Teal

(pre-order)

Clear

(pre-order)

Net Weight

750 g

Diameter Size

1.75 mm / 2.85 mm

Printing Settings

-

Printing temp: 210-230°C

-

Printing speed: 30-60mm/s

-

Bed temp: 25-60°C

-

Chamber temp: N/A

-

Fan: On

-

Dry settings: 70°C for 12h

-

Annealing: N/A

Application

PolyFlex™ TPU90, created from Covestro’s Addigy® TPU family offers the highest degree of flexability in the PolyFlex™ family.

With a shore hardness of 90A and an elongation to break of 585% this flexible filament is extremely soft while still being printable.

TPU90 is certified with ISO10993 allowing it to be used for medical and skin contact devices.

Key Features

Flexible with shore 95A

Extremely durable

Good printability

Colours

*pre-order (moq 3 unit, lead time 6 weeks)

Black

White

Red

Orange

Yellow

(pre-order)

Blue

(pre-order)

Net Weight

750 g

Diameter Size

1.75 mm / 2.85 mm

Printing Settings

-

Printing temp: 210-230°C

-

Printing speed: 20-40mm/s

-

Bed temp: 25-60°C

-

Chamber temp: N/A

-

Fan: On

-

Dry settings: 70°C for 12h

-

Annealing: N/A

Application

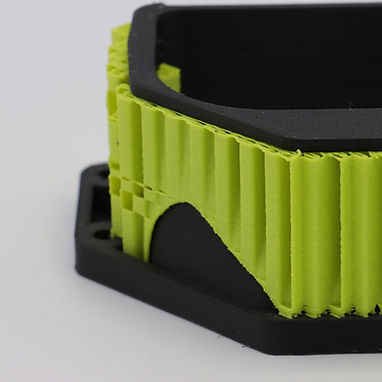

PolyFlex™ TPU95 is a flexible filament with a shore hardness of 95A.

Thanks to 3D printing, a model can be made more or less flexible depending on its design and infill.

PolyFlex™ TPU95 can be used in the footwear industry to print upper shoes, soles or insoles, to create flexible jigs and fixtures, and is commonly used to print custom gaskets.

Key Features

Flexible with shore 95A

Extremely durable

Good printability

Colours

*pre-order (moq 3 unit, lead time 6 weeks)

Black

White

(pre-order)

Clear

(pre-order)

Net Weight :

1kg

Diameter Size :

1.75 mm / 2.85 mm

Printing Settings :

-

Printing temp: 210-230°C

-

Printing speed: 20-40mm/s

-

Bed temp: 25-60°C

-

Chamber temp: N/A

-

Fan: On

-

Dry settings: 70°C for 12h

-

Annealing: N/A

Application :

Polymaker TPU95-HF can be printed faster than all other flexible filaments and all printing characteristics, such as, retraction and overhangs are improved.

Created from Covestro’s Addigy® family, TPU95-HF combines with its UV resistance, flexibility and high-speed printing.

Key Features :

Flexible with shore 95A

Extremely durable

Good printability

Colours

Black

Natural

Net Weight

750 g

Diameter Size

1.75 mm / 2.85 mm

Application

PolyMide™ CoPA provides excellent strength and a heat resistance up to 180˚C.

Warp-Free™ technology provides ease of printing with the outstanding mechanical and thermal properties natural to Nylon.

PolyMide™ CoPA is suited to parts in very demanding environments such as gears, engine brackets, pipe connectors or high velocity air flows.

Key Features

Printing Settings

-

Printing temp: 250-270°C

-

Printing speed: 30-50mm/s

-

Bed temp: 25-50°C

-

Chamber temp: N/A

-

Fan: Off

-

Dry settings: 80°C for 12h

-

Annealing: 70°C for 2h

High heat resistance

Balanced mechanical properties

Dimensionally stable during printing

Colours

Black

Net Weight

500 g

Diameter Size

1.75 mm / 2.85 mm

Printing Settings

-

Printing temp: 280-300°C

-

Printing speed: 60mm/s

-

Bed temp: 25-50°C

-

Chamber temp: 25-50°C

-

Fan: Off

-

Dry settings: 80°C for 12h

-

Annealing: 90°C for 2h

Application

PolyMide™ PA6-CF is a 20% carbon fiber reinforced Nylon 6 filament.

The carbon fiber reinforcement provides significantly improved stiffness, strength and heat resistance with outstanding layer adhesion thanks to Fiber Adhesion™ Technology.

PolyMide™ PA6-CF outperforms almost every 3D printing material, offering extreme durability and functionality while featuring a heat deflection temperature of 215°C.

Key Features

High heat resistance

Balanced mechanical properties

Dimensionally stable during printing

Colours

Grey

Net Weight

500 g / 2 kg

Diameter Size

1.75 mm / 2.85 mm

Application

PolyMide™ PA6-GF is a glass fiber reinforced Nylon 6 filament.

The material exhibits excellent thermal and mechanical properties without sacrificing the layer adhesion or printability.

PolyMide™ PA6-GF is strong, durable and features a heat deflection temperature of 191°C. It can be used in applications where stiffness and durability are paramount.

Key Features

Printing Settings

-

Printing temp: 280-300°C

-

Printing speed: 60mm/s

-

Bed temp: 25-50°C

-

Chamber temp: 25-50°C

-

Fan: Off

-

Dry settings:80˚C for 12h

(Only if the material has absorbed moisture) -

Annealing: 90˚C for 2h

High heat resistance

Balanced mechanical properties

Dimensionally stable during printing

Colours

*pre-order (moq 3 unit, lead time 6 weeks)

Black

(pre-order)

Net Weight

500 g

Diameter Size

1.75 mm / 2.85 mm

Printing Settings

-

Printing temp: 260-300°C

-

Printing speed: 30-60mm/s

-

Bed temp: 25-50°C

-

Chamber temp: 25-50°C

-

Fan: Off

-

Dry settings:80˚C for 12h

(Only if the material has absorbed moisture) -

Annealing: 80˚C for 6h

Application

PolyMide™ PA12-CF is a carbon fiber reinforced Nylon 12 filament.

The main advantage of Nylon 12 over Nylon 6 filaments is its low moisture sensitivity.

This improves the handling, storing and printing capabilities while still offering superior mechanical properties compared to other filaments.

Key Features

High heat resistance

Balanced mechanical properties

Dimensionally stable during printing

Colours

Clear

Net Weight

1 kg / 3 kg

Diameter Size

1.75 mm / 2.85 mm

Application

PolyLite™ PC is an engineering material which offers excellent strength and heat resistance.

Its transparency offers good light diffusion which makes it perfect for lighting applications.

Its strength can also be used to print utility hooks, brackets or other functional home items.

Key Features

Printing Settings

-

Printing temp: 250-270°C

-

Printing speed: 30-50mm/s

-

Bed temp: 90-105°C

-

Chamber temp: N/A

-

Fan: Off

-

Dry settings: 75˚C for 12h

(Only if the material has absorbed moisture) -

Annealing: 90°C for 2h

Heat resistant

Good light diffusion

Stiff and strong

Colours

Black

White

Net Weight

750 g / 3 kg

Diameter Size

1.75 mm / 2.85 mm

Printing Settings

-

Printing temp: 250-270°C

-

Printing speed: 30-50mm/s

-

Bed temp: 90-105°C

-

Chamber temp: N/A

-

Fan: Off

-

Dry settings: 80°C for 8h

-

Annealing: 100°C for 2h

Application

PolyMax™ PC is an engineering material with excellent heat resistance and outstanding durability.

It can be used for more demanding applications involving impact resistance and high vibration such as jigs and fixtures, furniture, small motor brackets, drones, 3D printer parts or prosthetics.

Key Features

Extremely tough PC

Heat resistant

Good layer adhesion

Colours

Black

White

Net Weight

1 kg

Diameter Size

1.75 mm

Printing Settings

-

Printing temp: 250-270 °C

-

Printing speed: 30-50 mm/s

-

Bed temp: 90-105°C

-

Chamber temp: 90-100°C

-

Fan: Off

-

Dry settings: N/A

-

Annealing: 100°C for 2h

Application

Polymaker™ PC-ABS is a PC/ABS polymer blend which offers excellent toughness and heat resistance while displaying a good surface finish and good compatibility with metal electroplating.

Polymaker™ PC-ABS characteristics make it ideal for automotive interior parts such as dashboard, door handles or instrument panels.

Key Features

Excellent toughness and heat resistant

Good surface finish

Compatible with metal plating

Colours

*pre-order (moq 3 unit, lead time 6 weeks)

Black

(pre-order)

Natural

(pre-order)

Net Weight

1 kg

Diameter Size

1.75 mm / 2.85 mm

Printing Settings

-

Printing temp: 260-280°C

-

Printing speed: 30-50mm/s

-

Bed temp: 100-115°C

-

Chamber temp: 100-110°C

-

Fan: Off

-

Dry settings: N/A

-

Annealing: 90°C for 2h

Application

Key Features

Good mechanical and thermal properties

Good toughness at low temperature

Good chemical resistance

Colours

*pre-order (moq 3 unit, lead time 6 weeks)

Black

(pre-order)

White

(pre-order)

Net Weight

1 kg

Diameter Size

1.75 mm / 2.85 mm

Printing Settings

-

Printing temp: 250-270°C

-

Printing speed: 30-50mm/s

-

Bed temp: 30-60°C

-

Chamber temp: 90-100°C

-

Fan: Off

-

Dry settings: N/A

-

Annealing: 100°C for 2h

Application

PolyMax™ PC-FR is a fire-retardant PC filament displaying strength and toughness whilst also achieving a V0 score in the UL94 flame retardancy test.

PolyMax™ PC-FR can reduce the intensity of a fire or slow/stop the spread of fire due to its self-extinguishing characteristics.

Key Features

Flame retardant

Strong and tough

Heat resistant

Colours

Black

White

Clear

Electric Blue

Polymaker Teal

Pink

(Pre-order)

Net Weight

750 g

Diameter Size :

1.75 mm / 2.85 mm

Printing Settings :

-

Printing temp: 190-220°C

-

Printing speed: 40-60mm/s

-

Bed temp: 25-70°C

-

Chamber temp: N/A

-

Fan: On

-

Dry settings: 60°C for 12h

-

Annealing: N/A

Beige

Slate Grey

Coral Red

Yellow

(Pre-order)

Orange

(Pre-order)

Green

(Pre-order)

Application :

PolySmooth™ offers the possibility to easily post process a model to obtain a smooth surface.

PolySmooth™ is designed for models which are hard to sand and post process such as figurines and cosplay props.

PolySmooth™ is also the ideal choice for product design and prototyping to present a clean design replicating an injection molded surface.

Key Features :

Safe and easy to post process

Excellent printability

Balanced mechanical properties

Colours

Natural

Net Weight

750 g / 3 kg

Diameter Size

1.75 mm / 2.85 mm

Application

PolyCast™ is an easy to print filament designed specifically for investment casting applications.

Featuring Ash Free™ Technology, 3D printed patterns in PolyCast™ can be completely vaporized when vitrifying the ceramic investment, typically leaving an ash residue of <0.003% by weight.

PolyCast™ significantly cuts down both the cost and lead time by eliminating wax injection mould tooling process.

Key Features

Printing Settings

-

Printing temp: 190-220°C

-

Printing speed: 40-60mm/s

-

Bed temp: 25-70°C

-

Chamber temp: N/A

-

Fan: On

-

Dry settings: 60°C for 12h

-

Annealing: N/A

Burn out cleanly

Safe and easy to post process

Excellent printability

PolyDissolve™ S1

PolyDissolve™ S1 is a water dissolvable support for PLA, TPU, PVB and Nylon based filaments from our portfolio.

It is specifically engineered to have a perfect interface with these materials while also displaying good solubility.

Colours

Natural

Net Weight

750 g

Diameter Size

1.75 mm / 2.85 mm

Application

PolyDissolve™ S1 is ideal for printing complex geometries such as art sculptures, figurines, models with internal cavities, all-in-one mechanisms or architectural models.

It is specifically engineered to have a perfect interface with these materials, supporting them while printing while also displaying accelerated solubility in room temperature water after printing.

Key Features

Printing Settings

-

Printing temp: 215-225°C

-

Printing speed: 30-40mm/s

-

Bed temp: 25-60°C

-

Chamber temp: N/A

-

Fan: On

-

Dry settings: 80°C for 12h

-

Annealing: N/A

Compatible with multiple materials

Good solubility

Excellent support interface

PolySupport™

for PA12

PolySupport™ for PA12 is a break away support for PA12 with no tools required.

Colours

Grass Green

Net Weight

500 g

Diameter Size

1.75 mm / 2.85 mm

Printing Settings

-

Printing temp: 270-300°C

-

Printing speed: 30-60mm/s

-

Bed temp: 50-80°C

-

Chamber temp: N/A

-

Fan: On

-

Dry settings: 80°C for 8h

-

Annealing: N/A

Application

PolySupport™ for PA12 is a break away support specifically engineered for PA12 based filaments.

It has a perfect interface with long-chain nylons, strong enough to support it and easily removable by hand.

PolySupport™ for PA12 prints at a similar temperature to PA12 and is compatible with open, enclosed and heated chambers.

The filament is colored green so its easy to see and remove after printing.

Key Features

Easy to break away

Perfect support

interface with PA12 based material

Good printability

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)