METALWORM specializes in robotic additive manufacturing, combining advanced toolpath strategies, real-time monitoring, and adaptive process control to deliver high-performance solutions.

By combining expertise in materials science and process optimization, METALWORM builds advanced robotic AM systems that support diverse materials and complex geometries for both research and industrial-scale use.

Technology

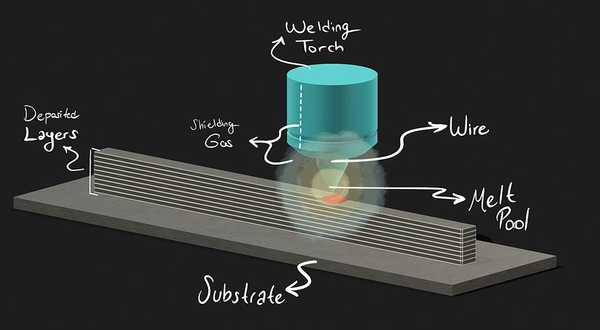

METALWORM uses a technology called Wire Arc Additive Manufacturing (WAAM), which is a layer by layer deposition of a continuously fed metallic wire using arc as the heat source.

Wire Arc Additive Manufacturing WAAM Diagram

High Deposition Rates

WAAM is known for its relatively high deposition rates compared to other metal additive manufacturing processes. This makes it suitable for manufacturing large-scale components or structures.

Cost-effectiveness

The use of wire as feedstock can be more cost-effective compared to other forms of metal feedstock such as powders. This can be advantageous for industries where cost efficiency is a significant factor.

Repair and Modification

WAAM can also be used for repair and modification of existing components, allowing for cost-effective and efficient repair of high-value parts.

Products

MetalWorm combines robotic precision with powerful software and materials science expertise. Whether you're exploring metal 3D printing in a lab or scaling up for industrial production, we provide a system that fits your goals.

Software

MetalWorm’s intelligent software suite powers every part of the robotic 3D printing process from planning to quality control which ensure precision, efficiency, and reliability.

MetalWorm Offline Program

From design to printing

Easily convert your 3D models into robot-ready instructions. Supports STL, STEP, and other standard formats with toolpath simulation for safe, optimized printing.

MetalWorm Control

Smart, adaptive printing

Automatically adjusts heat, torch height, and geometry during printing to ensure consistent, high-quality results every time.

Anomaly Detection (Advanced Option)

AI that keeps things on track

Machine learning watches for problems in real time and can take automatic corrective actions to keep your print on course.

MetalWorm Diagnostic

Monitor everything in real time

Tracks key data like welding current, temperature, and gas flow that gives you full visibility and traceability over every print.

Machine Vision (Advanced Option)

See what’s really happening

Uses cameras and sensors to monitor the melt pool, detect defects, and support advanced quality control during the build.

Digital Twin

Your virtual production assistant

Creates a live digital copy of your print process to help you predict issues, optimize performance, and reduce waste.